bandsaw blade width

We are the most professional manufacturer who offering high qualified BXTOOL-M51 Bi-metal Band Saw Blades, BXTOOL-M42 Premium Band Saw Blades, BXTOOL-M42 Classic Band Saw Blades, Carbide Tipped Band Saw Blades, BXTOOL Brand Lion, BXTOOL Brand Romance, bandsaw blade width, carbide bandsaw blade review, 137 inch band saw blades, designed to provide you more efficient quotation, professional advice and good after-sales service.

Feel free to talk to our online representative at any time you please using our Live Chat system on our website or one of the below instant messaging programs.

About Us

Founded in 1953, Benxi Tool Co., Ltd. started from the production of various cutting tools, and gradually transformed into a manufacturer specializing in the production of bi-metal band saw blades. The company integrates scientific research, production, and sales, and takes the pursuit of the best p... Read More

You May Like

-

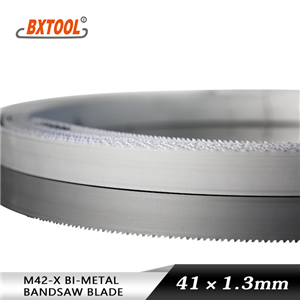

M42 metal band saws for metal cutting

Advantages:great stablity.cutting steel, aluminum, iron bar, steel pipe, copper,lead,non-ferrous metal, etc.High quality as well as Japanese.suitable for steel material mass production.high heat resistence and rust proof.

-

M42 Bandsaw Blades saw blade cutting stainless steel price

Band saw blade are used to cut carbon steel, tool steel, structural steel, stainless steel, pipes and tubes, die steel, angles and flat stock, and mixed metals

-

Bimetal M42 bandsaw blades

Application of Blade bandsaw b1 metal m42 hss german:High Speed Steel can be used in various applications, it features for resistant of high speed hardability, and it's ideal material for cutting blade. For carpenter's steel blade, high speed steel strip plays an important role.

-

tungsten carbide tipped woodcutting bandsaw blade for cutting hard wood

This kind of bandsaw blade is also suitable for cutting purposes of all kinds of soft wood, oak, maple, walnut and other hard wood precessed in furniture factory and workshops.

-

High quality bimetal band saw strip 34mm

Made in cobalt M42 high speed steel for the teeth tip and excellent tenacity steel material for the matrix. More teeth types, available for solid, hollow, profiles, bundle(more pieces)steel cutting, little material waste.

-

China supplier bandsaw blades

Good performance for metal cutting:The M42 Bimetal band saw blade should be used for cutting solid sections on a production basis, and bimetal band saw blade is particularly impressive on the more difficult to machine materials such as stainless steel,nimonic,titanium and nickel alloys.

-

M42 bimetal bandsaw blades Long working time for cutting pipe

The high speed steel edge offers durable, tough cutting ability, while the tempered alloy backer provides the fatigue resistance for long blade life.

-

customized carbide tipped bandsaw blade

Tungsten carbide tipped saw blades are widely used to cut wood, plywood, laminated board, plastic, grass, aluminum and some other metals.

-

M42/high speed steel bimetal bandsaw blades

Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth. The variable pitch design combines regular teeth of different pitches, gullet depths, and set angles for improved cutting and durability.

-

Mascot factory supplier bimetal bandsaw blade for pallet dismantler

Bimetal steel strips for bandsaw blade,Bimetal steel strip for hand hack saw blade,hacksaw blade bimetal strip steel,HSS M2 M42, D6A 6150 Spring Steel,hacksaw blade steel strips,Bi-metal strip steel,hacksaw blade strips,Bimetal material,saw blade material.

-

Bimetal Band Saw Blade with Positive Rake Variable Tooth

Application:Carbon Steels;Alloy Steels;Mold Steels;Aluminum/Non Ferrous;Stainless Steels;Tool Steels;Structural Steels.

-

Steel band saw blade for wood woodworking TCT bandsaw blade

This kind of bandsaw blade is also suitable for cutting purposes of all kinds of soft wood, oak, maple, walnut and other hard wood precessed in furniture factory and workshops.

-

construction steel cutting Bi-metal Bandsaw Blades

Ground mass is great, special spring steel and M42/M51 high-speed Cobalt steel;the two parts of the blade body and the teeths are heat treated respectively;the unfinished teeths are cylinder-shaped, And Welded to the blade body through high-energy;longer life, lower price.Width can be 41mm, 54mm, 67mm, 80mm, 100mm, 120mm; Forward angle can meet customers, 0° , 3° , 5° , any others.

-

Aluminum cutting bimetal bandsaw blade M42 band saw blade

The high speed steel edge offers durable, tough cutting ability, while the tempered alloy backer provides the fatigue resistance for long blade life.

-

Aluminum cutting bimetal bandsaw blade M42 bimetal band saw blade

Sectional size larger workpieces.Suitable for pipes,profiles,profiles and other materials,sawing material into bundles.

-

metel cutting bandsaw blades hss m42 bimetal blade

WOODCUTTING BANDSAWS: There is a wide range of what is considered correct for tooth patterns on a woodcutting bandsaw. The general rule is that fewer teeth per inch provide a faster, but rougher cut; and more teeth per inch provide a smoother, but slower cut.

-

M42 High-speed Cobalt Steel Band Saw blade

Our advantage of bone band saw blades:Has a particularly good corrosion resistance,Excellent oxidation resistance,High abrasion resistance,superior toughness.

-

M42 High Quality Bi-Metal Bandsaw Blade

Bimetal band saw blade is widely used in different kinds of fields, which can be used with any type of band sawing machine, for almost all types of metal continuous sawing, such as: structural steel, weathering steel, alloy steel, bearing steel, stainless steel, heat-resistant steel, aluminum , tool steel, etc.

-

High cobalt M42 HSS/Bimetal bandsaw blade

They are not combined through high-speed electron beam, but firstly heat treat respectively, then weld them together through high-energy, so that the saw would be more wearable, more red hardness and better fatigueresistance than that of the general technology.

-

steel tube cutting band saw blade

Band saw coil has a high speed edge material that has been electron beam welded to a fatigue resistant spring backing. If you are cutting in a production setting, you will want to use a bi-metal band saw blade that will cost more but is more economical in the long run.