carbide blade

We are the most professional manufacturer who offering high qualified BXTOOL-M51 Bi-metal Band Saw Blades, BXTOOL-M42 Premium Band Saw Blades, BXTOOL-M42 Classic Band Saw Blades, Carbide Tipped Band Saw Blades, BXTOOL Brand Lion, BXTOOL Brand Romance, carbide blade, swivel metal cutting bandsaw, industrial band saw blades, designed to provide you more efficient quotation, professional advice and good after-sales service.

Feel free to talk to our online representative at any time you please using our Live Chat system on our website or one of the below instant messaging programs.

About Us

Founded in 1953, Benxi Tool Co., Ltd. started from the production of various cutting tools, and gradually transformed into a manufacturer specializing in the production of bi-metal band saw blades. The company integrates scientific research, production, and sales, and takes the pursuit of the best p... Read More

You May Like

-

steel tube cutting band saw blade

ProductChina leading product bandsaw blades strips steel,Thickness 0.65mm-1.6mm,Width 13mm-80mm,Length as per your requirement,Material M2,M42,M51,B313,51CrV4,35CrV4,49CrMoNiV4-10,X32CrMoV4-1,6150,D6A,Technology Cold rolled.

-

metal cutting bimetal band saw blade

Product features:Excellent saw chip exhausting performance, cutting faster and straighter with little noise cutting surface is smooth and clean.

-

customized carbide tipped bandsaw blade

Tungsten carbide tipped saw blades: The saw blades' teeth are tipped (via welding) with small pieces of sharp tungsten carbide block.

-

M42 bi-metal bandsaw blade 27mmx0.9mm TPI 3/4

Product Profile:Bi-metal band saw blade, mainly refers to the band saw blades with high speed steel or other high performance steel tooth and low alloy spring steel saw belt.

-

tungsten carbide tipped woodcutting bandsaw blade for cutting hard wood

Woodcutting TCT bansaw blade performs exceptionally in cutting wooden material cutting. It holds the advantage of high speed, extended blade life, high wear and fatigue resistance, its ability to perform high speed straight line cutting will bring massive improvement to your workpiece quality and efficiency.

-

High cobalt M42 HSS/Bimetal bandsaw blade

Bi-metal saw banding uses M42/M51 high-speed Cobalt steel as teeth part and special spring steel as the blade body.

-

High Quality Band Saw Blade for cutting Metal

Description It is used widely. Can be used with ant type of band sawing machine.It suitable for almost all types of metal cutting in succession.Such as structural steel, weathering steel, alloy steel, bearing steel,stainless steel, heat-resistant steel, aluminum alloy, steel, etc.

-

Steel band saw blade for wood woodworking TCT bandsaw blade

Woodcutting TCT bansaw blade performs exceptionally in cutting wooden material cutting. It holds the advantage of high speed, extended blade life, high wear and fatigue resistance, its ability to perform high speed straight line cutting will bring massive improvement to your workpiece quality and efficiency.

-

High performance vertical bimetal bandsaw blades for band saw mill machine

Our advantage of used wood cutting band saw:The frame saw blade welding with carbide and stellite two alloys,has a particularly good corrosion resistance,excellent oxidation resistance,high abrasion resistance,superior toughness.

-

M42/high speed steel bimetal bandsaw blades

Bi-Metal band saw blades offer more cutting versatility and longer life through their unique construction, where a ribbon of high speed steel is electron-beam welded to a spring tempered alloy backer.

-

Bimetal M42 bandsaw blade/Material Bi-metal band saw blade

This bi-metal band saw blade is welded with two materials: Powder high speed(HSS) for the teeth and spring steel as back material.The tooth hardness is 68-69HRC(950HV-1000HV).

-

china bimetal band saw blades for plastic cutting with free shipping

Introduce for bimetal band saw blade Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth. The variable pitch design combines regular teeth of different pitches, gullet depths, and set angles for improved cutting and durability.

-

metal cutting bandsaw

Getting a balance between a good finish and a decent feed rate are the two objectives in determining how many TPI or teeth per inch you want to use. More teeth make a smoother but slower cut. Fewer teeth allow for faster cutting but with a slightly rougher finish.

-

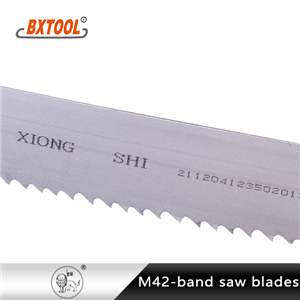

M42 High-speed Cobalt Steel Band Saw blade

Bi-Metal band saw blades offer more cutting versatility and longer life through their unique construction, where a ribbon of high speed steel is electron-beam welded to a spring tempered alloy backer.

-

Carbide Tipped Bandsaw Blade

Product Application Carbide Tipped Bandsaw Blade,specilized for hard wood, teeth parts is carbide of taiwan or gemany, saw teeth and body are different material.

-

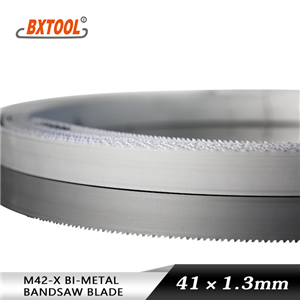

M42 High Quality Bi-Metal Bandsaw Blade

Bi-Metal band saw blades offer more cutting versatility and longer life through their unique construction, where a ribbon of high speed steel is electron-beam welded to a spring tempered alloy backer.

-

M42 bimetal bandsaw blades Long working time for cutting pipe

Bi-Metal band saw blades offer more cutting versatility and longer life through their unique construction, where a ribbon of high speed steel is electron-beam welded to a spring tempered alloy backer.

-

13*0.65mm High cobalt bimetal bandsaw blade 1/2*0.025 inch

Introduce for bimetal band saw blade:Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth.

-

Carbide Tipped TCT SKS51 Custom Bandsaw Blades for Wood Cutting

Sawmill power tool band saw blade body is made of durable carbon steel to ensure that the saw blade is soft and durable, increase the life of the saw blade, saw tooth material is carbide steel, increase the sharpness of the saw blade and made the band saw blade in using is more rapid and smooth.

-

M42 Material and Bimetal Band Saw Blade Type bandsaw blades

Product specification:This bi-metal band saw blade is welded with two materials: Powder high speed(HSS) for the teeth and spring steel as back material.The tooth hardness is 68-69HRC(950HV-1000HV).