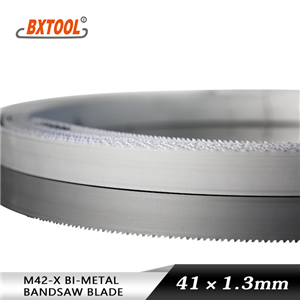

custom band saw blades

We are the most professional manufacturer who offering high qualified BXTOOL-M51 Bi-metal Band Saw Blades, BXTOOL-M42 Premium Band Saw Blades, BXTOOL-M42 Classic Band Saw Blades, Carbide Tipped Band Saw Blades, BXTOOL Brand Lion, BXTOOL Brand Romance, custom band saw blades, carbide tipped saw blades, bandsaw blade for aluminum, designed to provide you more efficient quotation, professional advice and good after-sales service.

Feel free to talk to our online representative at any time you please using our Live Chat system on our website or one of the below instant messaging programs.

About Us

Founded in 1953, Benxi Tool Co., Ltd. started from the production of various cutting tools, and gradually transformed into a manufacturer specializing in the production of bi-metal band saw blades. The company integrates scientific research, production, and sales, and takes the pursuit of the best p... Read More

You May Like

-

Hss M42 bandsaw machine use band saw blade with coil or roll supplier

Double metal band saw blade , mainly refers to the band saw blades with high speed steel or other high performance steel tooth and low alloy spring steel saw belt.

-

High cobalt M42 HSS/Bimetal bandsaw blade

Bi-metal saw banding uses M42/M51 high-speed Cobalt steel as teeth part and special spring steel as the blade body.

-

metal cutting bimetal band saw blade

Product features:Excellent saw chip exhausting performance, cutting faster and straighter with little noise cutting surface is smooth and clean.

-

High Quality Band Saw Blade for cutting Metal

Description It is used widely. Can be used with ant type of band sawing machine.It suitable for almost all types of metal cutting in succession.Such as structural steel, weathering steel, alloy steel, bearing steel,stainless steel, heat-resistant steel, aluminum alloy, steel, etc.

-

Hot Sale M42 Bimetal Bandsaw Blade

For the Bi-metal saw,the teeth are welded using cobalt-alloy with hardness reaching HRC69-70.M51 Tooth and Substrate jointing by laser after separately special spring steel heat treatment.

-

High performance vertical bimetal bandsaw blades for band saw mill machine

Our advantage of used wood cutting band saw:The frame saw blade welding with carbide and stellite two alloys,has a particularly good corrosion resistance,excellent oxidation resistance,high abrasion resistance,superior toughness.

-

china bimetal band saw blades for plastic cutting with free shipping

Introduce for bimetal band saw blade Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth. The variable pitch design combines regular teeth of different pitches, gullet depths, and set angles for improved cutting and durability.

-

Beams Cutting Band Saw Blade Bi-metal Bandsaw Blades

Product Description of metal cutting blade:Wide range of uses, efficient and durable – our M42 is a true all-rounder suitable for production cutting all types of metal.

-

Bimetal Bandsaw Blade

Features:The tooth edge has good hot hardness and the blade body offers excellent fatigue-resistance. It is suitable for cutting various ferrous and nonferrous at high speed.

-

M42 Bandsaw Blades saw blade cutting stainless steel price

Band saw blade has a high speed edge material that has been electron beam welded to a fatigue resistant spring backing.

-

M42 bi-metal bandsaw blade 27mmx0.9mm TPI 3/4

Product Profile:Bi-metal band saw blade, mainly refers to the band saw blades with high speed steel or other high performance steel tooth and low alloy spring steel saw belt.

-

High quality cost-effective Best sells in alibaba metal cutting Bimetal bandSaw Blade

Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth. The variable pitch design combines regular teeth of different pitches, gullet depths, and set angles for improved cutting and durability.

-

Bimetal M42 bandsaw blades

Products related Hss saw blade manufacturers:For welding: special procedure including pretreating and filler materials of base material composition;For machining: grinding, turing and milling;For plastic forming;For polishing;For electrical discharge maching, etc.

-

carbide bandsaw blades

Description of the diamond saw blade,Type: Diamond Cutting Tools,Blade Material: Diamond, Alloy Steel,Component: Blade matrix and segment.Processing: Cold press sintered, hot press sintered, braze welding, laser welding, electroplating.

-

Mascot factory supplier bimetal bandsaw blade for pallet dismantler

Wood bandsaw blade:Bandsaw Blade M42 Bi-metal strips,Bimetal bandsaw blade,Bi-metal Band saw Blade strips,Bi-metallic Band saw Blade,HSS M2 M42,D6A 6150 Spring steel,Bandsaw strips,M42 Bandsaw blade.

-

Bimetal M42 bandsaw blade/Material Bi-metal band saw blade

This bi-metal band saw blade is welded with two materials: Powder high speed(HSS) for the teeth and spring steel as back material.The tooth hardness is 68-69HRC(950HV-1000HV).

-

China factory supply bimetal bandsaw blades for wood

Specifications of M42 bi-metal bandsaw blades Import high quality material:A high cobalt M42 HSS cutting edge electron beam welded to a tough yet flexible alloy steel backing giving the blade and extremely hard cutting edge , while having a fully flexible back.

-

metal cutting bandsaw

Getting a balance between a good finish and a decent feed rate are the two objectives in determining how many TPI or teeth per inch you want to use. More teeth make a smoother but slower cut. Fewer teeth allow for faster cutting but with a slightly rougher finish.

-

bandsaw manufacturers wholesale metal cutting band saw

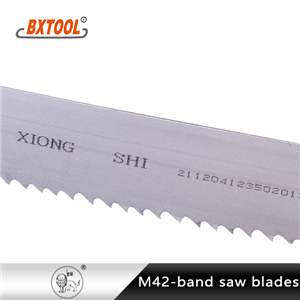

Specifications of M42 bi-metal bandsaw blades:M42 Bi-metal Bandsaw Blades are made of imported M42 high speed steel for edge and imported spring steel for backer by means of a series of advanced equipment and technique processing such as electron beam welding and specific heat treatment, etc.

-

HSS M42 bimetal band saw blade

The bimetal band saw blade was welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Cobalt) tooth. The variable pitch design combines regular teeth of different pitches, gullet depths, and set angles for improved cutting and durability.